Description

PRODUCTIVE SOLUTION for a wide range of applications, with increased feed per tooth and depth of cut.

SMOOTH CUTTING ACTION reduced spindle load, excellent chip evacuation and process stability.

TRUE 90° DEGREE with improved wall accuracy and straightness.

IMPROVED CHIP EVACUATION expands application range for low-power machines and small depths Of cut.

OPERATIONAL VERSATILITY offering an economic solution,

Available in Diameters 25mm – 125mm

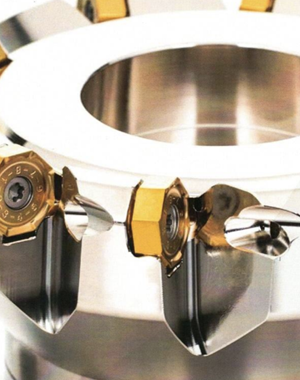

The LNEX 12 is a robust insert designed for shoulder milling with a maximum depth of cut up to 10 mm. It features a positive rake angle and narrow T-land to provide a smooth cutting action with lower demands on spindle torque.

The peripherally ground insert offers improved wall accuracy and straightness and creates a true 90° corner. The LNEX12 also features a patented U-groove segment on all four cutting edges which provide a good surface finish and expand its application range to low-power machines and small depths of cut.

In addition, the two-sided design supports performance by making ramping possible.

Reviews

There are no reviews yet.