Heule

Tool solutions from HEULE

HEULE’s innovations are centred on customer profitability. We provide standard tools and custom developments for a variety of applications.

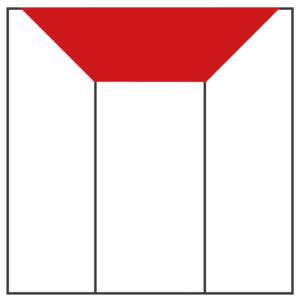

Deburring

The HEULE deburring tools deburr even and uneven bore edges, front and back in a single pass, without the need to rotate the workpiece or stop the spindle. They are universally applicable for both manual and CNC processes.

- Radius-shaped, consistent deburring result thanks to the defined cutting edge

- Uneven surfaces up to 30°

- Typical deburring size of 0.2 – 1.4 mm

- Can be used from a bore diameter of 1.0 mm

- Can be used for aluminium to nickel alloys / coated carbide blades

- Simple tool concept and operating principle for safe handling

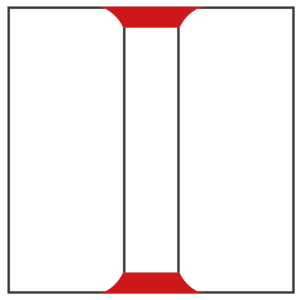

COFA

From bore diameter 2.0 mm: forwards and backwards deburring of even and uneven bores in one single pass

DL2

Bore diameter 1.0 mm to 2.1 mm: forwards and backwards deburring of even and slightly uneven bores in one single pass

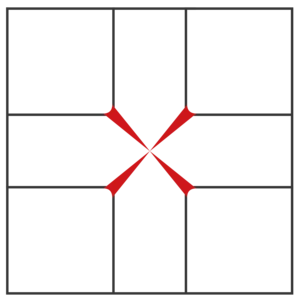

X-BORES

Customer-specific automated deburring solutions for intersecting bores or crossbores

Solutions for your specific application

Your application is not shown? We would be pleased to offer advice and develop a solution tailored to your needs.

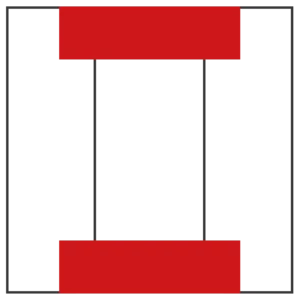

Chamfering

Maximum cost efficiency and process reliability

The HEULE chamfering tools remove burrs from bore edges by producing a uniform chamfer. The front and back of the bore can be machined in a single pass. They are particularly suitable for large batch size CNC operations.

- Controlled chamfering of both bore edges in a single pass

- Ready to use without pre-sets (SNAP)

- Suitable for reamed and finished bores

- Can be used on all materials / coated carbide blades

- Can be used from a bore diameter of 2.0 mm

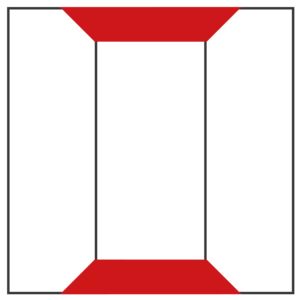

SNAP

Forwards and backwards chamfering in one single pass

DEFA

Forwards and backwards chamfering of interrupted bores – even with large burrs – in one single pass

Solutions for your specific application

Your application is not shown? We would be pleased to offer advice and develop a solution tailored to your needs.

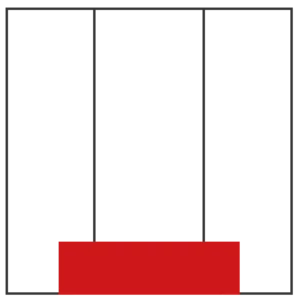

Counterboring

For maximum optimisation of the process

The HEULE counterboring tools machine the back of the bore without rotating the workpiece. The counterbores can be safely produced on the machine without any manual intervention.

- Counterbores up to 2.3 x bore diameter

- Cylindrical counterbores, formed counterbores, backspotfacing and chatter-free countersinking

- Interrupted cut possible

- Simple tool concept and safe handling

- Can be used on all materials / Carbide blade with material-specific coating

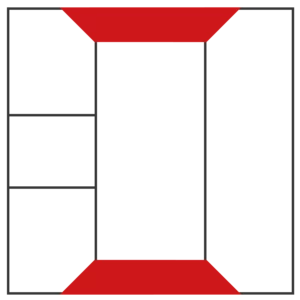

BSF

Backspotfacing up to 2.3 x the bore diameter

SOLO

Forwards and backwards counterboring and backspotfacing in one single pass. Interrupted cutting possible

GH-K

Countersinking of metal from Ø3 mm to Ø45 mm

Solutions for your specific application

Your application is not shown? We would be pleased to offer advice and develop a solution tailored to your needs.

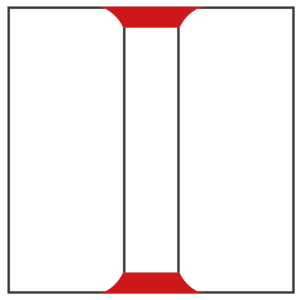

Drilling combined

High profitability guaranteed

HEULE’s combination drilling tools simplify production processes by combining drilling with deburring, chamfering or countersinking. Through customised development, the customer achieves the best possible process time optimisation.

- Execution of several work steps in a single pass – up to 3 functions in one drill combination tool

- Application-specific tools for different requirements

- Short set-up and non-productive times thanks to simple handling

VEX

Drilling combined with chamfering forwards and backwards in one single pass in the diameter range from 5.0 to 11.5 mm

Module Line

Your drill body combined with our chamfering module for simultaneous machining from bore-Ø 18.0 mm

Solutions for your specific application

Your application is not shown? We would be pleased to offer advice and develop a solution tailored to your needs.